Accelerate the pace of development of ACRON, the implementation of the factory workshop to re-build!

Time:

2019-10-09

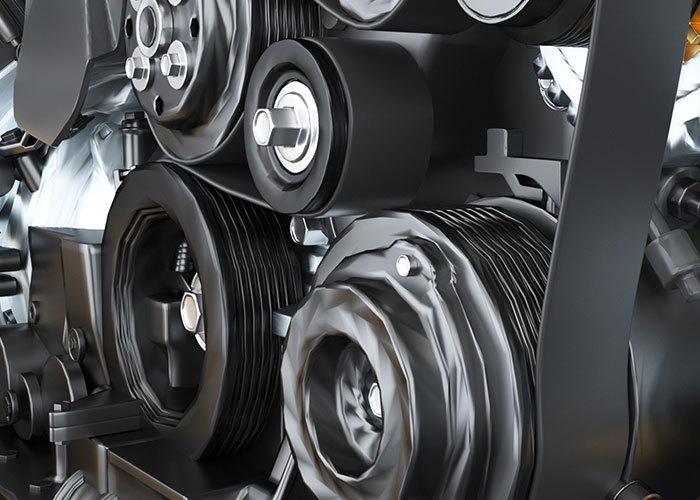

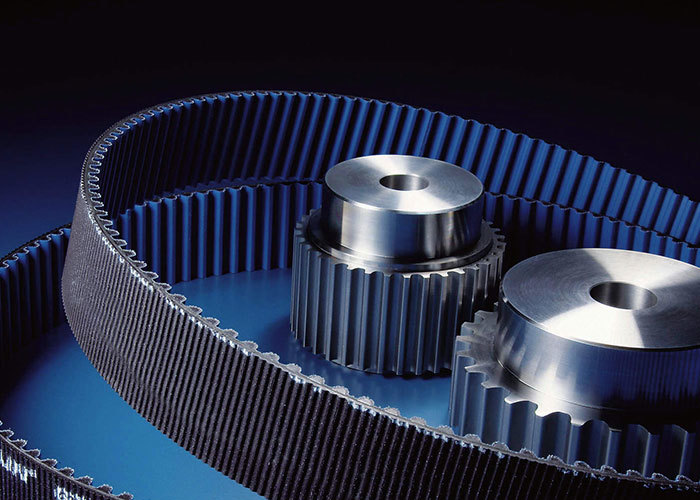

Southeast Shengsheng, Sanwu Capital, Qiantang has been prosperous since ancient times. Zhejiang ACRON Transmission System Co., Ltd. is located on the beautiful Qiantang River. It is a modern enterprise specializing in the design, manufacture and sales of high-precision automotive transmission belts and industrial belts. Founded in 2006.

ACRON has an annual production capacity of 10 million high-precision automotive transmission belts, with a total investment of more than US $10 million. The company regards quality as the life of the enterprise, strictly follows the quality policy of creating the greatest value for customers, and develops to the grand goal of China's first-class engine industrial belt manufacturer with the world's advanced level.

Implementation of workshop epoxy floor reconstruction

Nowadays, more and more enterprises of the factory, production workshop ground began to use epoxy floor, of course, ACRON is no exception. Epoxy floor with environmental protection, beautiful, dustproof, easy to clean and so on. If the factory workshop using epoxy floor can effectively avoid the ground to produce a lot of dust and sand and other phenomena.

As we all know, the dust generated on the ground is not only easy to get into the mechanical equipment in the factory workshop, resulting in the failure of the mechanical equipment, which not only delays the production of the factory and causes the order delay, but also costs the company a lot of money to repair the mechanical equipment, which causes great losses to the company. It is also easy to attach to raw materials and electronic components, causing trouble to product quality and production, and causing bad products, which will affect the company's brand image, or cause the company's economic losses!

For this reason, the person in charge of ACRON should build a factory workshop with high standards, build epoxy flooring, upgrade the workshop, and enable ACRON belts to be manufactured and produced on schedule, thus eliminating unnecessary errors.

For this reason, the person in charge of ACRON should build a factory workshop with high standards, build epoxy flooring, upgrade the workshop, and enable ACRON belts to be manufactured and produced on schedule, thus eliminating unnecessary errors.

Implement workshop 6S management

In order to improve the order of on-site management and improve production efficiency, ACRON comprehensively promotes the finishing, rectification, cleaning and safety work in 6S management in the factory workshop. What is 6S management? What is the effectiveness of 6S management for the company's employees? Presumably everyone has doubts, now please follow the editor to explore in the end!

Distinguish any items in the workplace as necessary and unnecessary, and eliminate everything except what is necessary to stay. Purpose: Free up space, flexible use of space, prevent misuse, create a refreshing workplace.

Put the necessary items left behind in accordance with the specified position, and place them neatly and identify them. Purpose: The workplace is clear at a glance, eliminating the time to find items, a neat working environment, and eliminating excessive backlog of items.

Clean the visible and invisible places in the workplace to keep the workplace clean and beautiful. Objective: To stabilize quality and reduce industrial injury.

Will organize, rectify, clean up to the end, and institutionalize, often maintain the environment in a beautiful state. Objective: To create a clear scene and maintain the above 3S results.

Each member develops good habits and follows the rules to do things and develops a proactive spirit (also known as habituality). Objective: to cultivate good habits, abide by the rules of the staff, to create a team spirit.

Pay attention to the safety education of members, and have the concept of safety first at all times to prevent problems before they occur. Objective: To establish a safe production environment, all work should be based on the premise of safety.

Since the implementation of the 6S rectification, the production workshop has first made great efforts in sorting, rectification, cleaning and safety. The production materials, operation area and finished product pile have been greatly improved compared with before. This not only greatly improves the image of the workshop visually, but also improves the overall production efficiency!

Xiaobian believes that in the future, the ACRON belt will be better and better, and move forward for our grand goal!