Analysis of various causes of timing belt fracture and failure! [ACRON Lecture Hall]

Time:

2020-10-17

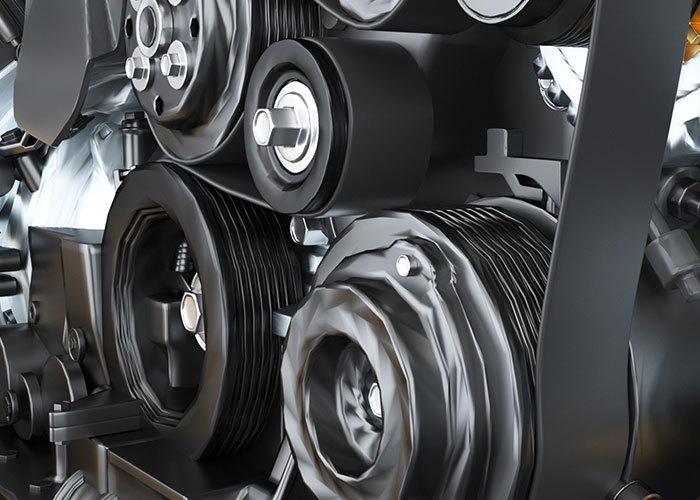

As we all know, the timing belt is one of the important parts to ensure the normal operation of the automobile engine. It needs to accurately coordinate various important parts of the engine. If it is damaged, the valve and ignition will be disordered or stopped. In severe cases, the valve may even be broken and the piston may be pushed through, resulting in the need for overhaul.

Since the timing belt is a rubber product, it is prone to aging, cracking, and disconnection after a long time. Manufacturers will take into account such consumption and wear when recommending the replacement cycle of the timing belt.

Therefore, the damage caused by normal wear and tear generally does not occur during the recommend replacement cycle; otherwise, it means that the timing belt is not working properly and there must be other problems. Problems with the operation of the tensioner, idler, guide wheel, some external pollution or damage, incorrect installation, etc., will cause problems with the timing belt.

Today, Xiao Bian will discuss it with you!

What are the reasons for the damage of the timing belt?

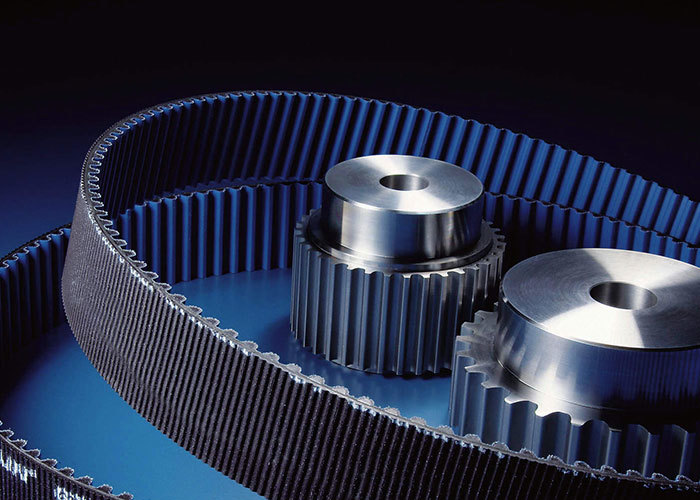

Any defect on the timing belt will cause the life of the belt to end prematurely, whether it is a small crack on the belt, an imperfection of the synthetic material, a nick or a cut, etc. Nowadays, with the advancement of belt manufacturing technology, these problems have been well solved, and there are few problems in this area.

Idler and deflection roller rotation is not flexible

These pulleys are used to keep the timing belt aligned under tension and run on the correct trajectory, while minimizing the "drift" effects that cause belt damage.

If the pulleys cannot rotate freely due to inferior bearings, damaged bushings, bent shafts, or improper lubrication, the timing belt will slide on the surface of these pulleys, causing friction and heat or smoothing the surface of the belt. In addition, frictional heat generation will accelerate the aging of the belt, and the smoothness of the surface will weaken the transmission of the belt, thereby affecting its timing function.

Incorrect operation of the tensioner

Whether it is a smooth pulley or a toothed pulley, just like an idler pulley or a guide pulley, the tension pulley also needs to provide proper tension and rotate freely. Therefore, when the tensioner does not work correctly, just like the idler pulley and the guide pulley, it will have a great impact on the working life of the timing belt.

According to maintenance experience statistics, if there is a problem with the tensioner or idler but it is not replaced, this will cause the timing belt that has just been replaced to fail again. Or, on the other hand, if the new belt just replaced fails, 50% of it is caused by not replacing the tensioner or idler with the problem.

Inaccurate alignment

When talking about the service life of the timing belt, we rarely discuss the impact of the uncorrected belt guide on it, but this factor is very important.

When working, each timing belt moves around its trajectory at a speed of thousands of revolutions per minute. The huge friction generated by the opening and closing movement of this surface contact will cause the belt to be damaged in advance. Therefore, before and after installing the timing belt, we must carefully check the installation position of each component of the timing system to see if it is accurately aligned, so as to avoid the timing belt caused by the inaccurate installation position. damage.

External contamination or damage

Anything in contact with the timing belt may damage the timing belt, which is why the entire system is covered when the timing belt is working. However, even if most of the timing belt is protected, there will still be a small amount of oil in the engine, such as engine oil, coolant, etc., affecting the timing belt, causing it to slip or chemically corrode.

In addition, small stones, small metal chips or other debris may also drill into the timing belt area through their respective paths, which may also damage the belt.

Incorrect installation

This is the part we can most successfully control, as long as we strictly follow the instructions. Do not use a lever or screwdriver to forcibly pry the timing belt to extend it into the normal track, because the timing belt is designed to be non-extensible.

When installing, release the tension on the timing belt, put the timing belt on the track first, and then restore the tension. Use special positioning and tensioning tools to install, so that you can ensure that the timing belt is installed, positioned and tensioned correctly, and that all components can rotate smoothly.

How long is the replacement cycle of the timing belt?

At the same time, the driving habits and maintenance habits of car owners will also have a certain impact on the service life of the timing belt. In addition, when the timing belt is usually replaced, other related accessories, such as idler, tensioner and water pump, will be replaced at the same time.