[ACRON Lecture Hall] Analysis of Various Causes of Automobile Belt Fracture Failure!

Time:

2020-04-23

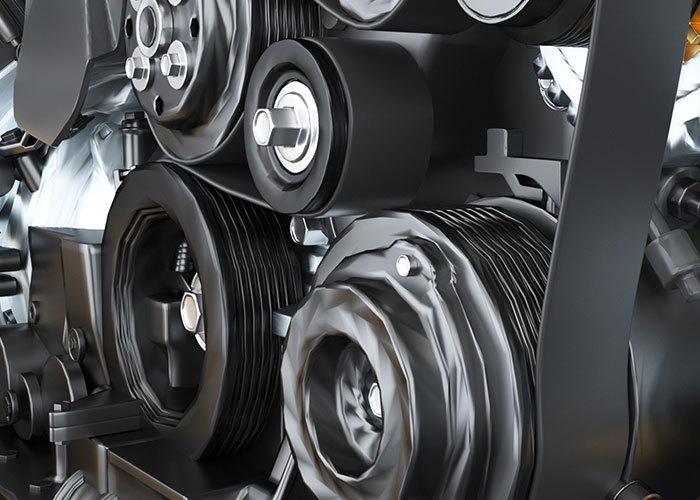

There are actually many reasons for the failure mode of the timing belt, but it is difficult for ordinary people to determine. Many small partners often suffer from no relevant knowledge and experience, and do not know how to deal with various situations.

In response, the theme of this week's Anglo Lecture is--Analysis of various causes of timing belt fracture failureIt is convenient for everyone to take appropriate preventive measures and corrective actions in advance.

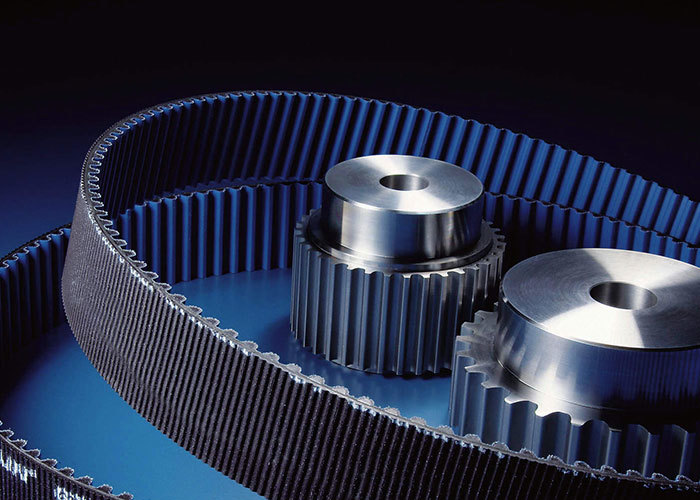

Normally, after 2 to 3 years of belt operation, the core wire has reached the fatigue life. At this time, the belt failure is normal and no improvement measures need to be taken. As shown below, this is a jagged 45-degree angle.Serrated broken beltIt is the typical belt core wire that has reached the normal fatigue life.

When the tension of the belt is too low during installation, tooth skipping may occur. When it is forced to return to the wheel groove, it will often bend violently and instantaneously at the contact point with the pulley, which will eventually cause damage to the belt core wire. If the pulley and back idler are below the specified minimum, there is an idler between the belt and the pulley, or even if the belt is bent by hand at a small acute angle, the belt will fail.

In addition, when foreign matter enters the transmission system, a sharp corner will be formed between the belt and the pulley, which will cause the belt core to bend. Using a tool to force the belt onto the pulley can also cause damage to the belt. Although it will not fail immediately, the overall life of the belt will decrease.

03. Impact load

When the driven equipment requires intermittent or periodicTorque load greater than normalThe impact load in the transmission system will appear, and the severe impact load can cause the belt core wirefracture in the form of a rough uneven, As shown in the figure below.

04. Belt installation tension is too high

In order to prevent such wear problems, the appropriate belt installation tension value must be accurately set.

Belt tooth jump means that the teeth of the belt climb out of their corresponding wheel grooves, and their roots are no longer under load. When the tooth part rolls, the rubber can tear from the tooth root along the core wire. As the tear range spreads, the belt tooth part starts to detach from the belt in a strip shape.

Generally, increasing the belt installation tension can effectively prevent the belt from jumping teeth prematurely. If it is useless, it may be that the transmission system structure is not strong enough to prevent deviation. The pulley diameter can also be increased to allow the belt to transmit higher loads at low tension.

06, the belt wheel is not parallel

The belt failure, often from the tooth root crack or from the belt side of the largest bearing tension began to tear, and extended to the entire belt width, eventually leading to belt tooth shear. Due to the relatively large tension of the fiber, the side where the belt is squeezed seriously may also have obvious wear, and the belt may climb out or roll to the edge of the pulley.

One is that few people will go to check the pulley carefully, thinking that it is only the belt's own problem. When the belt runs on a pulley of problematic size, the tooth side will be highly worn, and the canvas on the side of the belt will be fuzzy fluffy or flaky.

After the belt is worn, its core wire will contact with the pulley, which will cause the outer circumferential groove of the pulley to wear. The protrusion of the tooth top of the pulley is a sign of the wear of the pulley. A heavily worn pulley is usually:Wheel groove wear and reduction of machining outer diameter of pulley. The typical performance of belt failure caused by wear pulley is:Grinding damage of belt tooth bottom and regional dimensional deformation of teeth.

08. Pulley runout

At the end of the article, summarize some suggestions on timing belts:

Different brands of timing belts have different mileage, but no matter what brand, it is best not to exceed 80000 kilometers, and replace them in time when they reach 80000 kilometers.

-

In the normal driving process, do not drive the vehicle with overcrowding, overloading, or overloading. This will greatly increase the loss speed of the timing belt and increase the probability of accidents.

-

If you want to replace the timing belt, remember to find a trusted auto repair shop to replace it, so that the quality is more guaranteed, and it is safer and more directional.